With hydrogen production on the rise, green hydrogen takes centre stage. Many countries are embracing this new technology to support their decarbonisation strategies. As a result, electrolysis manufacturers and hydrogen producers must rely on sophisticated water treatment plants to supply the required volumes of pure water.

VWT is at the forefront of water treatment for green hydrogen production. We provide end-to-end guidance and the latest technology for small and large organisations worldwide.

Reliable water source

A crucial part of the green hydrogen production process is access to purified water. Both electrolyser manufacturers and hydrogen producers must have water treatment technology that creates a constant supply of purified water.

This becomes even more challenging in water scarcity locations where you must be able to purify any available water source cost-effectively. It’s also critical for remote locations. For example, offshore platforms using wind power or desert-based production plants using solar power.

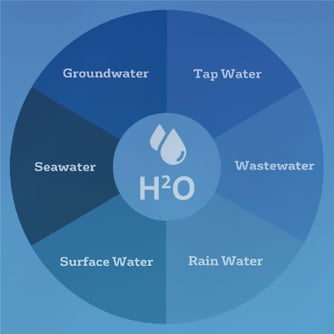

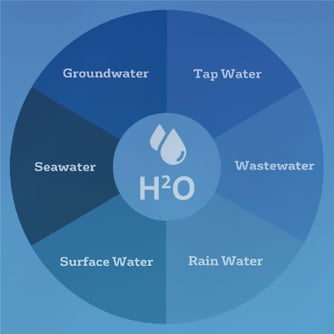

Veolia can help you identify the most effective water source in your location. We can also provide suitable technology for purification. By assessing viable raw water sources - such as groundwater, seawater, surface water, tap water, and wastewater - our experts help you make an intelligent choice.

We then install cost-effective pre-treatment and purification methods, using suitable technology for your chosen water source and location. This typically involves reverse osmosis, ion exchange, and continuous electrodeionisation.

Maximising electrolysis cell life

Electrolysis cells are a costly aspect of hydrogen production from water. So, you’ll want to maximise their service life. It’s also crucial cells operate efficiently to produce the most hydrogen from your equipment. Water quality can significantly impact the performance and longevity of electrolysis cells. By maintaining water purity standards you avoid harmful deterioration from pollutants and minimise energy consumption. Lean on our water technology expertise to finetune your treatment process and achieve more from your electrolysis cells. Having the right water treatment technology in place can lower your hydrogen production costs. It can also enhance the productivity of your entire process and extend the life of expensive assets.

Cost-saving hydrogen production technologies

It makes commercial sense to use as many hydrogen production byproducts as possible in your process. Our technology can help you achieve this for wastewater, oxygen, and thermal heat.

We can install further processes to treat wastewater. This will reduce your overall water cost. Once redundant, the wastewater feeds back into the purification process, instead of discharging with no further benefit.

Hydrogen production using water and electrolysis creates oxygen. We can divert this resource back into your water pre-treatment facilities, reducing your treatment costs. We can even help you divert thermal heat (created during hydrogen production by electrolysis) to a productive use, such as aquaculture (in northern Europe). Having technology that helps you use byproducts effectively makes sense. For sustainability and the profitability of your operations.

Veolia provides expert guidance when using water to produce green hydrogen. Installing the most effective technology for your site, enjoy full productivity. Plus, rely on our global presence to maintain your system for its entire life.

Back to the Hub page>>